The traditional 3D printing additive manufacturing technology plays an important role in printing macro size structure, but its manufacturing accuracy is limited, which is difficult to meet the stringent requirements for printing accuracy in the field of micro, precision manufacturing, such as: the printing accuracy in MEMS and microfluidic chips is required to reach the micron level; In the field of micro/nano optics, the printing accuracy of the character of photonic products is required to reach the order of 100 nanometers. The traditional fused deposition 3D printing technology is difficult to meet the application in the high-precision field. In this trend, the UV curing 3D printer came into being.

1/ Industrial SLA 3D printer

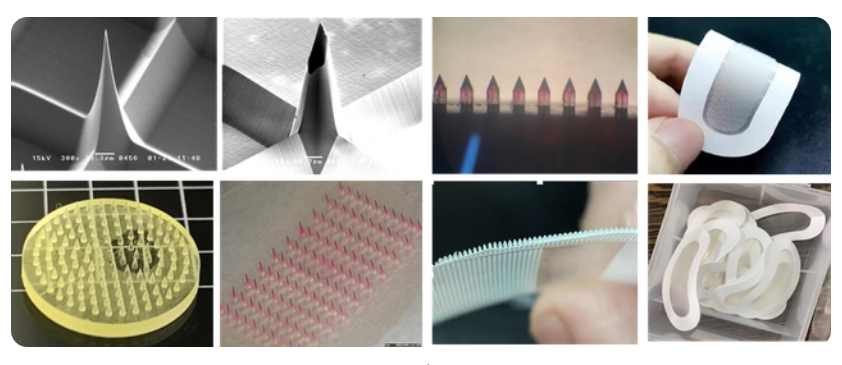

SLA 3D printing technology is one of the advanced manufacturing technologies at the forefront of the world at present. In 2014, it was rated as one of the top ten disruptive innovative technologies of the year by MIT. Its principle is to print the required model shape on the printing platform by using the method of direct laser radiation or projection of a specific wavelength, and create three-dimensional micro nano structures by stacking them layer by layer, because it can produce complex three-dimensional structures of micro nano scale, It has the characteristics of high precision, high efficiency, material saving, convenience and rapidity, and has a wide range of applications in MEMS, micro/nano photonic devices, microfluidic devices, biomedical and other fields.

Industrial micro nano light curing 3D printer

Forming range: 50mm * 100mm * 100mm

Print accuracy: 3 μ m

Technical principle: sub pixel micro scanning technology, one-time molding

Exposure principle: 405nm upper array exposure

03.3D Print Application Case

Post time: Dec-14-2022