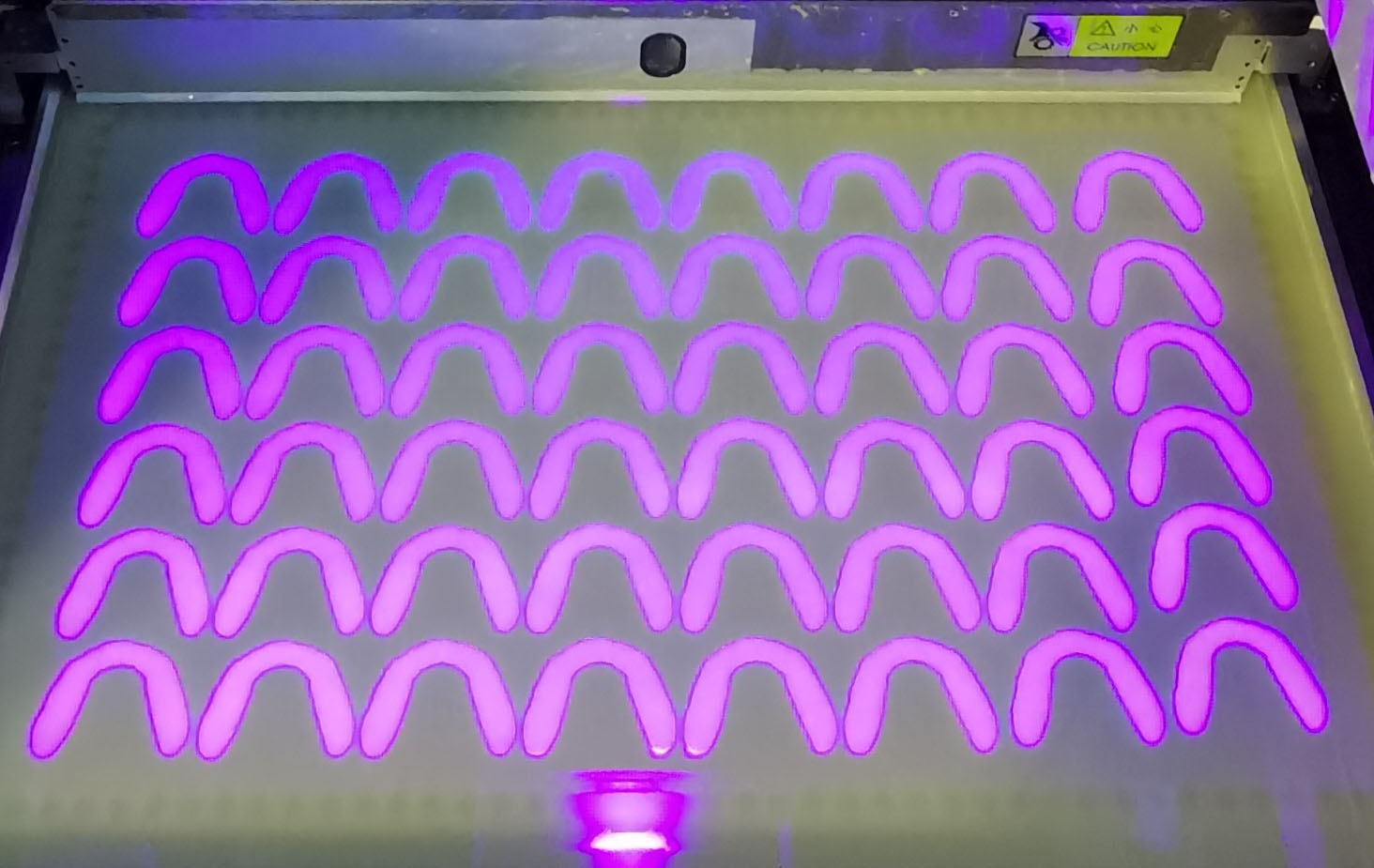

With the little improvement of market personalization and customization demand, the application of UV curing 3D printing technology has become more extensive. The UV curable 3D printer is a combination of digital and technical products. It has a strong ability to copy and customize and is especially suitable for industries with high customization requirements. The application of the dental industry is a typical case. It is certain that the application of light curing 3D printers in the dental field is very mature at this stage, and dentists usually need to customize appropriate denture aligners for everyone. Compared with traditional plans, 3D printing is not only more accurate, but also greatly reduces the cycle and cost.

More than 4 million people in the United States wear orthotics. According to incomplete statistics, traditional orthotics use wire, which makes users feel uncomfortable and affects their aesthetics. According to a senior dentist, they have been looking for solutions with more perfect manufacturing technology and lower cost. At present, they also feel that they have achieved certain results, and they have reached the forefront in the application of 3D printing technology in the dental field and can provide users with more excellent treatment effects. The light curing 3D printer is definitely a choice that is more in line with the user experience and can meet the manufacturing requirements of high-quality orthotics.

At present, customized transparent plastic dental brackets (orthodontics) are used in foreign markets, which are more comfortable to wear, can be disassembled and cleaned, and are almost invisible. The most important thing is that in the early stage, 3D software is generally used for accurate modeling. Because the timely adjustment of cases can also be tracked and analyzed during the treatment process, the treatment plan fully conforms to the actual situation of users. The 3D printed orthotic devices are very accurate, which can be said to completely change the practice of correction.

For 3D printing equipment, the most desirable are scalability and maintainability, which can fully meet the personalized needs of the market. The market of orthodontic appliances is expanding rapidly, growing at a double-digit annual growth rate, and 3D printing technology is developing more rapidly. It is expected that in the future, the light curing 3D printer will continue to bring new possibilities to the dental field, and the dental 3D printer will also draw its own grand blueprint in this market.

Although 3D technology has significant advantages in this field, because it requires a new kind of working logic, software, scanner and printer training, and some confidence in these innovative processes, the adoption of 3D technology may frighten some practitioners.

Therefore, the future of the dental 3D printing industry is encouraging. Many enthusiasts regard technology as a good way to improve their efficiency and intervention safety. In fact, the 2018 report of SMARTech Publishing shows that the annual growth rate of 3D dental printing is 35%, and it will reach 9.5 billion dollars by 2027. This report considers the hardware, materials and parts of 3D printing.

Post time: Dec-28-2022